White Paper: Modernising Collision Repair Compliance

Why Leading OEMs Are Replacing Annual Audits with Real-Time, Cloud-Based Compliance Systems

Audience: OEM Network Managers & Compliance Leaders

Author: OUTSORC, Providers of MONITRR – Continuous Compliance and Network Improvement for Sales and After-sales Networks

Executive Summary

Annual audits expose OEMs to months of undetected compliance risk and a higher probability that “compliance drift” across the network increases.

Continuous compliance provides real-time oversight, more intelligent resource allocation, and stronger network engagement – providing a more comprehensive assessment of network status, especially when this is supported by Artificial Intelligence (AI).

Leading SaaS systems empower OEMs with proactive risk detection, audit readiness, and improved shop relationships: moving from reactive to proactive.

Industry leaders are already making the switch as the cost of waiting increases and repurposed legacy systems constrain decision-making and consume budget unnecessarily.

The OEM mindset is shifting from viewing network compliance as a necessary cost to the basis of strategic advantage.

Introduction: The Compliance Gap No One Talks About

OEM-certified collision repair shops are critical to brand integrity, vehicle safety, and customer trust. Yet the dominant audit model (annual or biennial, on-site evaluations) is no longer adequate. As a leading OEM put it: “Knowing a shop is fully compliant one day a year isn’t so advantageous anymore and is becoming prohibitively expensive to manage quality assurance this way...especially when our organisation races towards digitisation…”

What happens between audits? Most OEMs don’t know.

As vehicles become more complex and customer expectations more demanding, relying on rearview compliance data can expose the entire network to unnecessary risk. This paper explores why forward-looking OEMs are adopting continuous compliance through leading business-to-business Software as a Service (SaaS) platforms, like MONITRR, and how it positions them for long-term success.

The Limits of the Annual Audit Model

1. Infrequent Oversight

Annual or biannual audits are snapshots, not patterns. Audits are often scheduled in advance, providing ample preparation time to get everything “just perfect” for the Auditor.

2. Lagging Risk Detection

Issues may go unnoticed for 6 to 24 months – “compliance drift” – such that customer safety and other legal obligations are not performed in the intervening period.

3. Inefficient Resource Use

Low-risk and high-risk shops are audited equally and using the same ‘tried-and-tested’ audit template. A deep dive into a specific area of shop compliance or more frequent audits of underperforming shops isn’t on the agenda. This is magnified by audits performed by an army of subcontractors or sub-subcontractors who rush to complete the audit format at multiple shops and brands on the same day.

Why Continuous Compliance is the New Standard

1. Real-Time Visibility into Network Compliance

Know and track compliance status for the whole network and individual shops throughout the year with trending analysis.

Set the thresholds for automated alerts to shops so they act on non-compliance straightaway and track Audit Action completion in real-time.

See shop performance evolve in real-time and allocate resources in a proactive way to minimise network risk.

Best Practice: Enable a hybrid approach to risk management – network self-assessment followed by remote audits and onsite audits informed by AI risk assessment.

2. From Raw Data to Actionable Intelligence

Leading SaaS solutions continuously analyse the network’s compliance status, validating the accuracy of self-assessment evidence submitted, identifying and alerting manufacturer operating standards that require action, and utilising AI to review shop behaviour and past activity to identify risks. Some, like MONITRR, even automate Action Plans for individual shops.

Instant and live dashboards that provide compliance status by region, country, state and zone, rather than manually creating PDFs using spreadsheet data analysis.

Drives smarter decisions and proactive interventions.

Best Practice: Shift the perception of compliance and certification away from cost management to strategic or competitive advantage. For example, OEMs can demonstrate continuous and live compliance status to insurers.

3. Smarter Audit Allocation

Focus costly on-site audits on shops with the highest risk profile and repeat ‘offenders’ flagged by the system, rather than by default performing on-site audits on every shop unnecessarily.

Enable AI-Assist to create Action Plans for shops based on their compliance status and risk profile.

Audit network Focus Areas – standards and issues that have a high priority.

Perform targeted remote audits to validate shop self-assessment evidence submission at a fraction of the cost of on-site audits.

Best Practice: Use risk-based prioritisation for high-impact audits.

4. Built for Today’s Fast Pace

Provide 100% control and flexibility to the OEM so they can manage their compliance/certification program the way they want and introduce changes immediately.

Supports programs within programs, for example, reporting on ADAS and EV manufacturer operating standards separately and simultaneously, and enabling OEM Field Teams to create personal networks with reporting and dashboards.

Ensures readiness with validated, updated data and compliance status.

Enables new standards to be introduced instantly.

Best Practice: Enable OEM programs to provide multiple job roles and seniority levels with individualised user access, network analysis and reporting.

5. Transparent, Engaged Shop Relationships

Shops see their compliance status dashboards with network benchmarking.

Shops receive a monthly, automated and OEM-branded compliance status report.

Shops receive proactive and OEM-branded alerts and notifications requiring shop action.

Alerts guide self-correction.

UX professionals have designed modern SaaS solutions to ensure the user experience of shops is easy, quick and intuitive.

Best Practice: OEMs control and drive network improvement through relationship-building rather than fear.

6. Enterprise-Grade Security and Scalability

Modern SaaS solutions have independent, annual penetration tests and quarterly vulnerability tests to ensure high security levels are maintained.

Modern SaaS solutions are independently audited to ensure they comply with GDPR and local data privacy conditions.

Modern SaaS solutions provide tailored user access by job role, seniority, geography, and network responsibility. These are controlled and edited by the OEM in real time.

Modern SaaS solutions are cloud-based, so network scaling is straightforward.

Best Practice: Cloud-based systems housed on a leading cloud computing platform like Microsoft Azure or AWS, with the application itself subject to separate, regular and independent data and system security verification.

7. Audit-Readiness and Legal Defensibility

Full digital audit trail – who did what, when, how and why.

Timestamped, exportable data with customisable content.

Evidence of continuous risk monitoring against the manufacturer’s operating standards as opposed to a once-a-year inspection.

Shop self-assessment evidence is retained in the ‘cloud’ and retrievable in seconds to avoid disagreement over past OEM-shop compliance status.

Remote audits can be performed 24/7 using the shop’s live compliance status.

Best Practice: Ensure continuous audit-readiness and the capability to analyse trends in shop compliance status.

Dispelling Common Misconceptions

Case Study: Large OEM Raised Continuous Compliance by 62.5%

Challenge: A leading OEM faced low levels of compliance and rising quality assurance costs across its global CRN with limited management control and flexibility using its legacy network platform.

Solution: Adopted MONITRR for real-time monitoring and risk-based audit scheduling.

Outcome:

CRN shop engagement increased by 146%.

System costs fell by 61.5%.

The time taken to develop shop Improvement Action Plans fell from an average of 1.5 hours to several minutes.

More time focused on repair quality instead of unnecessary compliance verification, as this was performed online before site visits.

Key Characteristics of Best-In-Class Compliance Systems

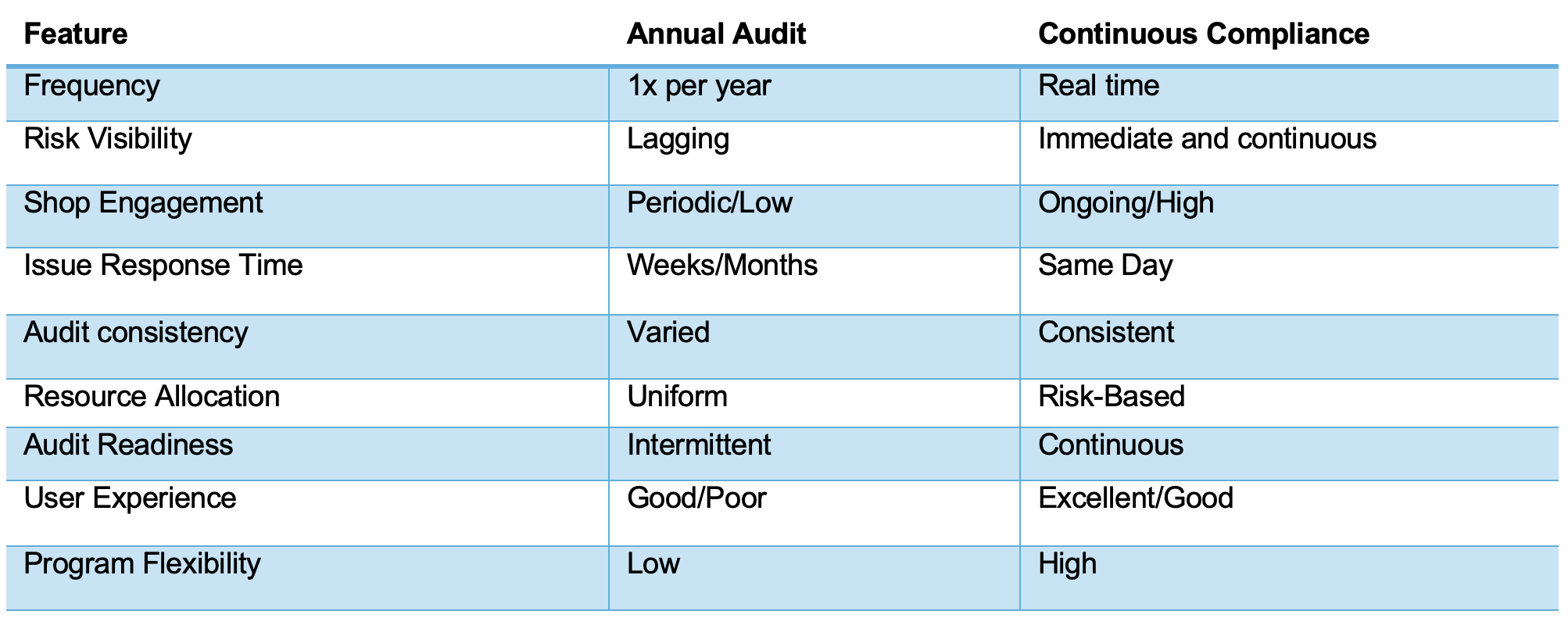

Visual Comparison: Annual Audit vs. Continuous Compliance

Transitioning with Confidence

OEMs understandably worry about transitioning legacy processes. Leading SaaS platforms like MONITRR often lead the onboarding process with minimal distraction for the primary customer stakeholders. A seamless, quick and hassle-free transition usually has the following components:

A dedicated onboarding team to plan and manage the whole process. These draw on a wealth of experience and expertise from onboarding similar customers.

Access to bespoke administration tools to expediate the program setup phase.

Utilising cloud storage for customer upload/download of historic data.

Incorporating a ‘soft launch’ to test program functionality, user access and data analysis before a national/global program roll-out.

Onboarding tracking tools to monitor the progress of the roll-out and user engagement.

A clear, timely and structured user training platform tailored to use face-to-face meetings between the onboarding team and customer stakeholders to review progress and adjust the roll-out plan if required.

Conclusion: Compliance is No Longer a Once-a-Year Responsibility

Annual audits belong to a less complex time. Today’s collision repair environment demands continuous visibility, agility, and partnership.

SaaS platforms like MONITRR empower OEMs to:

Reduce compliance risk and incorporate AI-risk profiling to prioritise and focus audits.

Reduce blind spots and compliance drift, which are often common in once-a-year audit programs.

Make evidence-based decisions with ‘live’ network data analysis and insights.

Strengthen the relationship between OEM and CRN shops.

Cut costs without cutting corners with AI and automation and purpose-built user interfaces.

It’s more than compliance – it’s confidence, clarity, and control at scale.