From Compliance Checks to Repair Excellence: How Technology Is Transforming OEM Collision Repair Audits

For many years, OEM collision repair audits followed a familiar and necessary structure. Auditors spent the majority of their on-site time validating compliance with OEM operating standards - reviewing facilities, tools and equipment, and technician training records. While this ensured baseline conformity, it left limited opportunity to assess the most critical outcome of all: the quality of repairs to customer vehicles.

Compliance has always been essential, but it has never been the end goal. The true purpose of an OEM certification programme is to ensure vehicles are repaired correctly, safely, and consistently in line with brand standards. Today, modern audit technology and Artificial Intelligence are enabling OEMs to realign their audit programs with that objective.

A Measurable Shift Enabled by Technology

Advances in digital platforms, remote inspections, and AI-driven evidence review have fundamentally changed how audits are performed. Compliance verification can now be completed quickly and accurately before an auditor arrives on site, dramatically reducing the time required for physical checks during the visit.

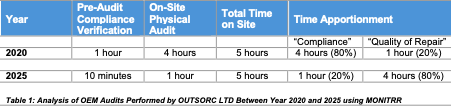

The impact of this shift is clear when comparing audit time allocation over recent years:

Analysis of OEM Audits Performed by OUTSORC LTD Between Year 2020 and 2025 using MONITRR.

While the total audit time remains unchanged, technology has enabled a dramatic rebalancing. What was once a compliance-heavy exercise has evolved into an audit model that prioritises repair quality and operational excellence.

Higher-Value Audits, Better Conversations

With compliance efficiently verified in advance, auditors can now use their on-site time far more effectively. Rather than working through checklists, they can focus on higher-value activities that directly improve network performance, including:

Assessing the quality and consistency of vehicle repairs

Reviewing internal processes and identifying operational improvements

Evaluating housekeeping and workshop organisation

Supporting customer experience and service delivery

Identifying parts sales and commercial opportunities

Reviewing equipment capability and future investment needs

Strengthening collaboration between OEMs, dealers, and repairers

This transforms the audit from a transactional inspection into a collaborative engagement that adds value for both the OEM and the repair partner.

Stronger Outcomes for OEM Certification Programs

Crucially, this approach does not require more time or resources. Instead, technology ensures that each audit delivers deeper insight, clearer validation of repair quality, and greater confidence that certified shops are meeting OEM expectations in real-world conditions.

For OEMs, this means improved visibility across the network, greater repair consistency, and stronger protection of brand reputation and vehicle safety. For repairers, it means more meaningful interactions with auditors, clearer guidance, shared network best practices, and a stronger partnership with the OEM.

The bottom line? Compliance is about verifying that the shop can repair vehicles correctly. Quality of Repair is about demonstrating that the shop does this. Shops don’t repair more vehicles by being compliant. They do so by adopting network best practices. Imagine doing both effortlessly, using advanced technology, to get more out of your audit team.

Looking Ahead

As vehicle technology continues to advance - driven by new materials, electrification, and ADAS - OEM certification programs must evolve in parallel. Legacy audit models are no longer sufficient to scale networks or validate repair quality at the level required today.

Digital platforms and AI are no longer optional enhancements. They are foundational tools for building faster, smarter, and more effective audit programs - programs that move beyond compliance alone and focus on what truly matters: ensuring vehicles are repaired right, every time.